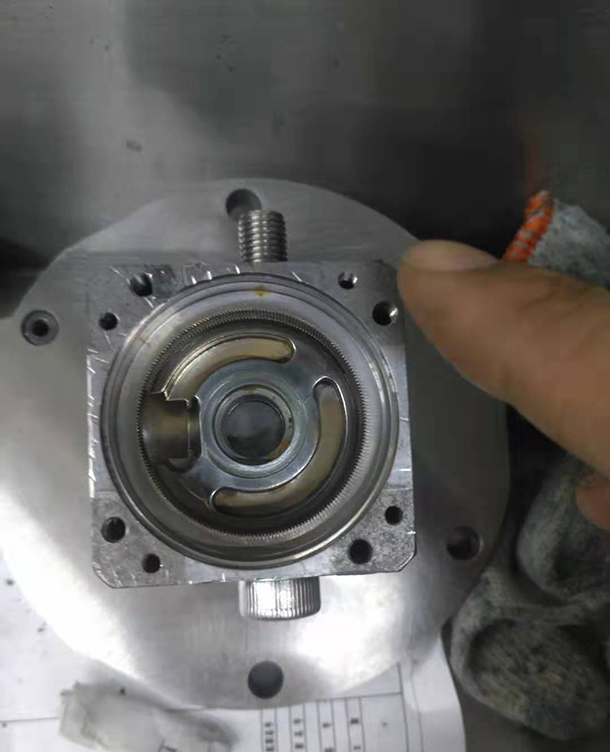

The introduction of self abrasive fluid into various metal machining and 3D printing object fields in China has solved the process problem of difficult removal of burrs in the complex cavity intersections, cross holes, and cavity flow channels. At the same time, abrasive fluid abrasives adhered to the substrate, after being squeezed into the complex cavity and cleaned, always have some residues inside the complex cavity, which cannot be fully inspected and detected by endoscopes, Ultimately, it leads to secondary contamination of the parts and makes them unusable,

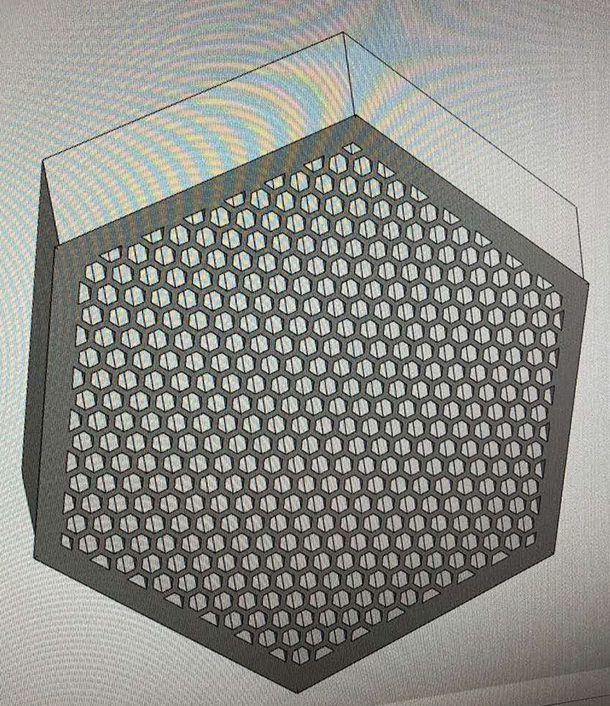

After years of continuous research and development, Putzmai Precision Machinery has finally adopted a combination of cleaning machine tools and abrasive colloid decomposition solution to completely solve the process problem of complex grinding cavity residues that cannot be removed. The cleanliness of the cleaning cavity is above 0.1, which solves a very headache process problem for the polishing of the inner cavity of the complex cavity blades of aircraft engines and the residual cleaning of grinding cavities such as 3D printing honeycomb cooling channels.